A CERAMIC-BASED COATING WITH HYDROPHOBIC AND OLEOPHOBIC PROPERTIES. PERMANENT PROTECTION AT HIGH AND LOW TEMPERATURES, CHEMICAL AND WEATHER RESISTANT WITH EXCELLENT EASY-TO-CLEAN PROPERTIES.

WHAT IS ERSTOPHOB?

erstophob is a transparent, ready-to-use ceramic coating for the protection of non-absorbent surfaces with a high hydrophobic and oleophobic effect.

The coating chemically bonds to the substrate after application. After curing at room temperature, erstophob effectively protects the surface against water, oils, dirt and even paints and varnishes, as well as against any atmospheric influences.

erstophob forms a highly transparent protective layer without changing the original appearance and surface texture of the substrate.

The ceramic-based coating forms a hydrophobic and oleophobic protective shield on the applied surfaces, which not only repels water and oil, but also prevents paints, varnishes and dirt from adhering to the surfaces, or allows them to adhere very poorly. One of the effects of the protective layer is an easy-to-clean effect.

- Protection against paint, varnish and markers, atmospheric influences and UV radiation.

- Suitable for almost all materials

- Fluorine-free and highly transparent

- No influence on appearance and surface quality

- No change in fire properties

- Low material consumption

- Application and curing at 5 to 30°C

- Temperature resistance of cured coating -50° to 850°C (1200°C for short periods).

- Resistant to acids, weak alkalis, alcoholic, ketone-based and other organic solvents

- Hardness of cured surface: 5.5-6.5H pencil hardness, contact angle >100°

APPLICATION

erstophob is particularly suitable for smooth, non-absorbent surfaces, e.g.

- Polyurethane or epoxy systems

- Polyester lacquers

- Plastics GRP

- Glass

- Aluminium

- Zinc

- Stainless steel

- Copper

- Brass

- Bronze

- powder coated surface

- lacquered surfaces

- galvanised metals

- marble, ceramic, granite

Examples of application areas:

- Vehicle paints

- Aluminium rims

- Traffic signs

- Aircraft

- Boats

- Rail vehicles, buses

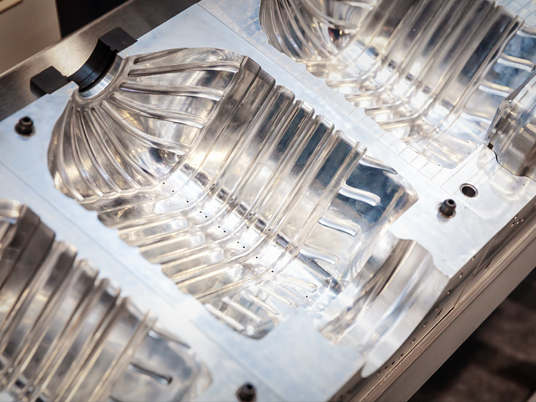

- Moulds

- Containers

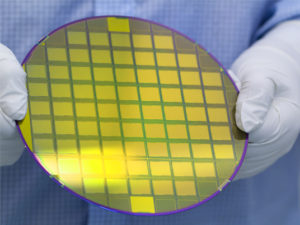

- Chip manufacturing